The Biker Build-Off and the Birth of the World’s Fastest Bagger

In 2006, Klock Werks was invited to compete in the Discovery Channel’s Biker Build-Off, a televised competition series that showcased builders from across the motorcycle world. Each builder had to complete a unique custom build within a specific time frame, culminating in a head-to-head competition.

At the time, baggers were not typically seen as performance-focused bikes. They were viewed as large, comfortable touring machines rather than custom or high-performance builds. Klock Werks, however, took a different approach. Rather than opting for a flashy chopper or custom cruiser like many competitors, Brian Klock and the team chose to build a performance-oriented bagger, a risky move, as the industry wasn’t yet recognizing baggers for their performance potential.

Despite the unconventional decision, our bagger stood out. The bike's blend of performance, unique style at the time, and function not only won them the Biker Build-Off competition but also sparked the idea that baggers could push boundaries in both customization and speed.

Winning the Biker Build-Off wasn’t the only goal. We had a bigger vision—to take the bagger to the legendary Bonneville Salt Flats to test its speed capabilities. Bonneville is known as a proving ground for speed records, where vehicles of all kinds are pushed to their limits on the vast, flat salt surface. The team knew that the performance bagger had potential, but the Salt Flats would be the true test.

In their first run at Bonneville, the bike performed impressively, but something was holding it back from reaching its full speed potential. Laura Klock, who piloted the bike, reported hitting a “wind wall,” where the bike seemed to struggle against the wind at higher speeds. Although the bike ran well, it was clear that to break speed records, they needed to find a way to better manage the aerodynamics of the motorcycle.

It was during the drive home from Bonneville that the breakthrough came. While reflecting on the bike’s performance and brainstorming ways to improve it, Brian Klock had a simple yet powerful realization. As his kids played with the wind, hands out the window, Brian joined in and felt the wind force pushing his hand down. That was the moment when the connection between air management and the bike’s speed issues clicked. Could wind force be causing the bike to lift at high speeds?

Brian and the team began brainstorming how they could alter the bike’s front end and fairing to better control the airflow and give the bike more stability. They created a series of small adjustments, including reshaping the windshield, aiming to use the wind to their advantage rather than fighting against it.

A Game-Changing Innovation

The next year at Bonneville, their adjustments paid off. The newly designed windshield not only helped the bagger break land speed records, dubbing it the World’s Fastest Bagger at the time, but also significantly improved its stability and handling. The once-overlooked detail of aerodynamics turned out to be a game-changer.

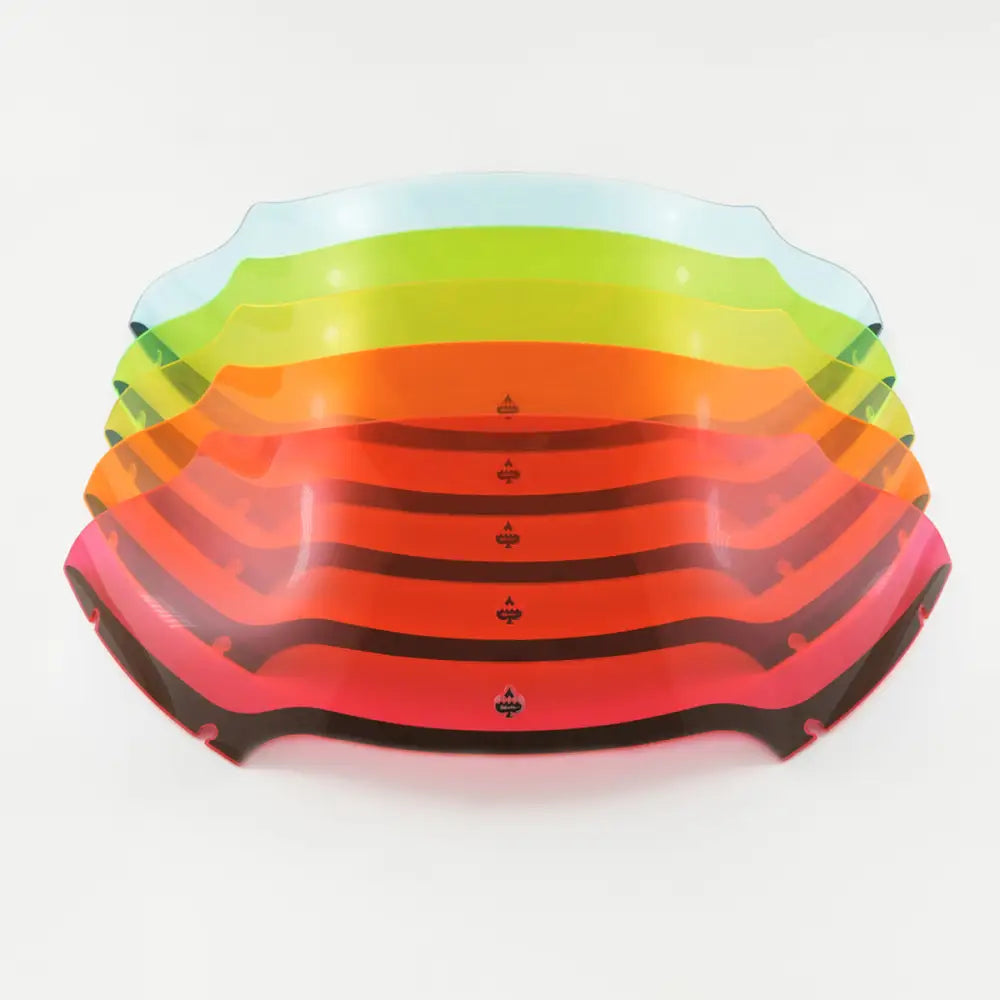

From there, the team took the redesigned windshield to the wind tunnel for further testing. They wanted to ensure that this new innovation wasn’t just a one-time success on the Salt Flats, but something that could provide lasting benefits to everyday riders as well. After rigorous testing, the Flare® Windshield was perfected—not only for speed, but for stability and handling.

Seeing the success of the Flare® Windshield at Bonneville and with the growing popularity of performance baggers, the Klock Werks team made the bold decision to bring this product to market. However, they didn’t just stop with Bonneville; they wanted to ensure that the Flare® would work for all riders across different motorcycle models.

The team conducted extensive R&D to ensure the Flare® Windshield delivered real benefits to riders of all kinds—whether they were cruising on the highway or pushing limits at higher speeds. The result was a product that not only enhanced the look of a bike but also delivered proven improvements in air management. The unique design of the Flare® redirects airflow to reduce buffeting, increase downforce, and improve overall handling.

Why We Are Air Management Experts

Our experience in the Biker Build-Off, our time at Bonneville, and the meticulous research that followed set the foundation for Klock Werks' claim as air management experts. We didn’t just create a product; we tackled a real-world challenge by mastering the science of airflow and applying it directly to motorcycle performance.

The Flare® Windshield is more than just a windshield—it’s a meticulously engineered air management system that transforms how wind interacts with the motorcycle. Its signature “hips” on either side of the shield are designed to channel airflow around the rider, significantly diminishing buffeting—the turbulent gusts that can unsettle stability and increase rider fatigue.

The “flip” at the top of the Flare® Windshield is where the true magic happens. By flipping the airflow up and over the rider, the windshield creates downforce, much like a spoiler on a race car. This downforce keeps the front of the motorcycle planted firmly on the ground, enhancing stability, especially in crosswinds or when riding at higher speeds. We’ve proven this over and over again—whether it’s in race settings or during long-distance touring rides, the Flare® consistently delivers improved handling and control.

This innovation isn’t merely theoretical; it has undergone rigorous evaluation in the A2 Wind Tunnel in Mooresville, North Carolina, a facility highly regarded in the automotive and motorsports worlds for its precision testing capabilities. Testing at A2 provided the ideal conditions to simulate high-speed airflow, enabling us to perfect the Flare® design with exacting adjustments that ensure it excels under the most challenging conditions.

From the Bonneville Salt Flats to real-world highway miles, the Flare® consistently delivers a smoother, more stable ride, maintaining control even in high-speed and crosswind situations. This level of performance is a testament to Klock Werks’ commitment to advancing air management for every rider, every ride.

The combination of the hips and flips not only makes for a more comfortable and controlled ride, but it also showcases our deep understanding of air management. Through research and development, we’ve optimized the Flare® Windshield to perform across multiple models and styles of motorcycles, ensuring that every rider experiences the benefits of superior airflow control.

The Flare® Windshield has revolutionized the way riders experience their motorcycles. With its unique design, born from the Salt Flats and refined in the wind tunnel, it’s no wonder that riders from all over the world trust Klock Werks to enhance their bike’s performance, stability, and comfort. We are committed to continuing our role as pioneers in air management, bringing innovations that make a difference on every ride.